4.9 min read

Paper moulds: stronger than you think

Yes, it’s paper. No, it doesn’t burn. Here’s the engineering hiding in paper baking moulds.

In our daily lives, there are many things we overlook simply because we take them for granted.

But have you ever asked yourself how it’s possible that paper moulds don’t burn when you put them in the oven? Simple truths often rest on complex foundations.

So, what makes paper of paper moulds resistant to heat?

You might think it’s just a clever chemical solution. But the truth is more interesting.

Let’s find out together!

It all starts with the right raw material

What looks like just paper moulds are actually carefully engineered tools.

Its secret? Two key factors:

• Fiber composition

• Material structure

First things first, the right material must comply with regulations.

Do our materials comply with the standards for food-contact and oven-tested materials? Absolutely!

It’s not just a legal requirement, it’s the foundation of our quality and reliability. Our paper moulds comply with key regulatory requirements, including:

- Regulation (EC) 1935/2004 on materials and articles to come into contact with food with regards to raw materials and additives.

- Regulation (EC) 2023/2006 on good manufacturing practice (GMP) for materials and articles intended to come into contact with food.

- FDA, CFR (Code of federal regulations) 21 Food and drugs, USA

- Recommendations for food contact BfR XXXVI/2. Paper and paperboard for baking purposes.

These key regulatory requirements are fundamental in ensuring our products meet the highest safety standards. This commitment to safety and quality starts with the materials we use.

But, also, the right raw material will have specific features to withstand such extreme temperatures. Paper baking moulds are made using virgin fiber pulp, a pure, high-quality source of cellulose with very low levels of impurities. And that’s no small detail.

The virgin cellulose fibers that make up paper contribute to greater mechanical strength and, by limiting degradation, allow for higher thermal resistance, suitable up to 220°C (428°F).

But that’s not all.

Purity provides the quality characteristics that make the paper suitable for its intended applications.

This means the paper moulds don’t tear, deform, or collapse, ensuring a smooth and reliable baking process from start to finish.

In addition, there are some paper moulds that are often made with pleated sides or reinforced bases which help to maintain their shape in all situations for performance suitability, such as oven or freezer.

More grammage, more performance: is it true?

You’ve probably heard that paper moulds with higher grammage is better but that’s not always true.

In fact, higher grammage contributes to superior structural integrity and rigidity during baking especially important for products with high moisture content or long baking times.

However, thanks to our technical expertise and ongoing testing, we also offer thin paper moulds with excellent baking performance.

Through precise fiber orientation, specialized coatings (when required), and strict quality control, we ensure that even low-weight papers maintain their shape, release performance, and resistance in the oven.

Fiber orientation: the power of alignment

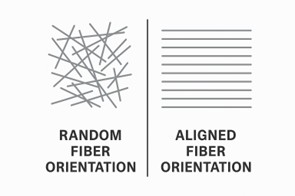

Fiber orientation refers to the direction in which the cellulose fibers in paper are aligned during the paper-making process.

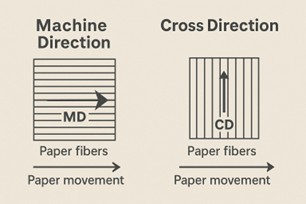

In technical terms, this alignment can be either machine direction (MD) – the direction the paper moves through the machine – or cross direction (CD) – perpendicular to that flow.

In high-performance baking papers, precise fiber orientation means the fibers are intentionally aligned in a way that optimizes the paper’s strength, flexibility, and thermal stability depending on its final application.

An optimised orientation of fibers increased paper’ strenght, flexibility and thermal stability compared to a paper with a random fiber orientation

Two different fiber orientations: Machine direction vs Cross direction

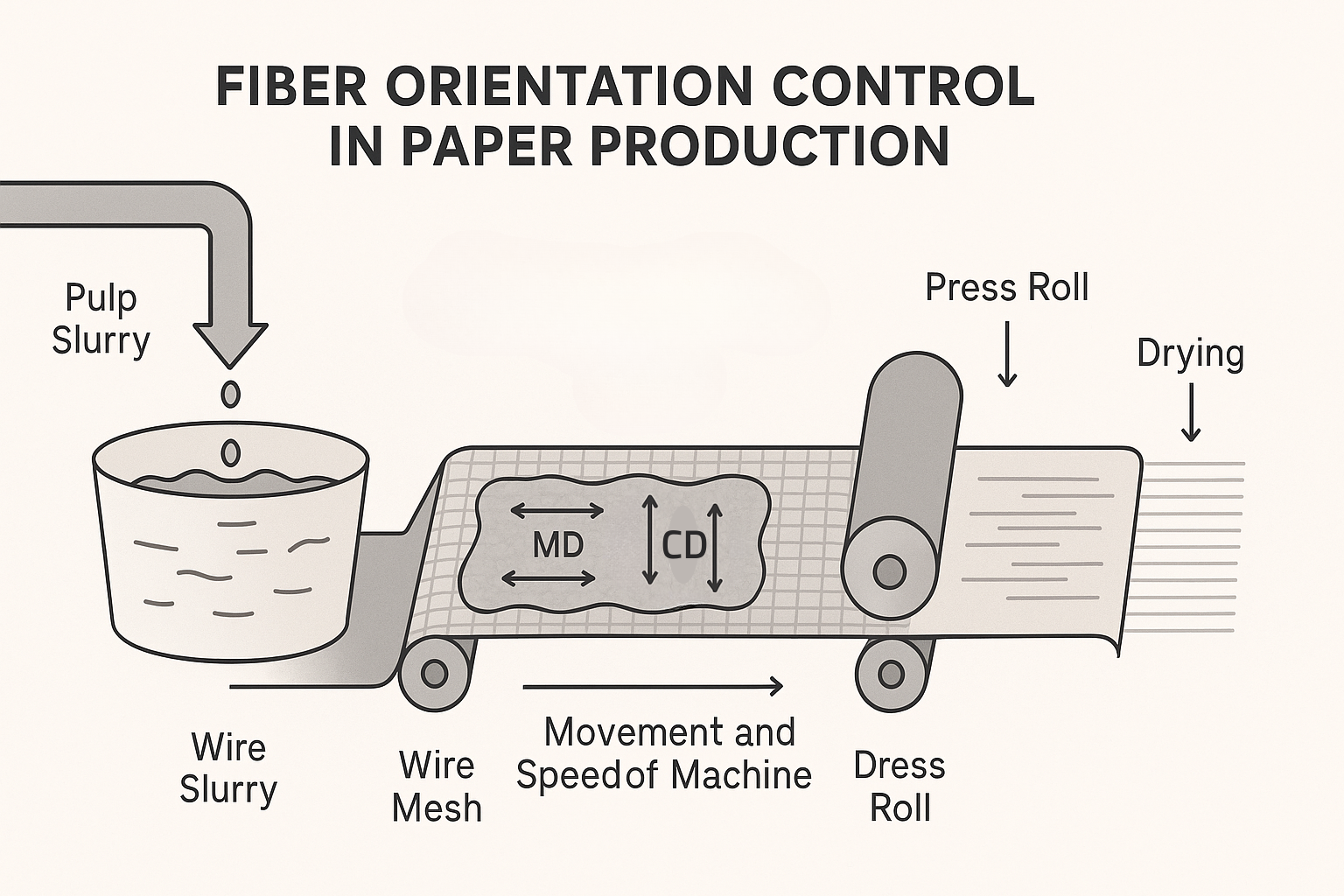

How it’s achieved

During the paper production process, the pulp slurry is deposited onto a moving wire mesh. The movement and speed of the machine, combined with flow control and drying methods, influence how the fibers settle and dry. By adjusting these variables, manufacturers can engineer the fiber orientation to suit specific technical requirements.

The process of fibers orientation in industrial production

Crazy how many engeneering processes there are behind a such a simple product, right?

Do you find our articles useful? If so, please comment or send us a message on our LinkedIn company page!