4.3 min read

Industrial baking cup: the hidden complexity in 1 simple thing

Have you ever wondered what story lies behind a product like industrial baking cup?

Every physical object that surrounds us and that we use in our daily lives is the result of a process far more complex than we might imagine.

In the bakery and confectionery industry, for example, behind what may look like a simple industrial baking cup lies a whole world of processes and expertise.

By the time the product reaches the consumer’s hands, the many steps and professional skills involved are no longer visible. That small industrial baking cup, seemingly so simple, is in fact the result of the work of hundreds of people, all committed to ensuring it is available at the right time and in the right place.

The quality, safety, and innovation that define these products require highly coordinated and complex industrial processes.

It all starts long before the industrial baking cup takes shape

It begins with a question: how can food performance, sustainability, and reliability be guaranteed in just a few grams of paper?

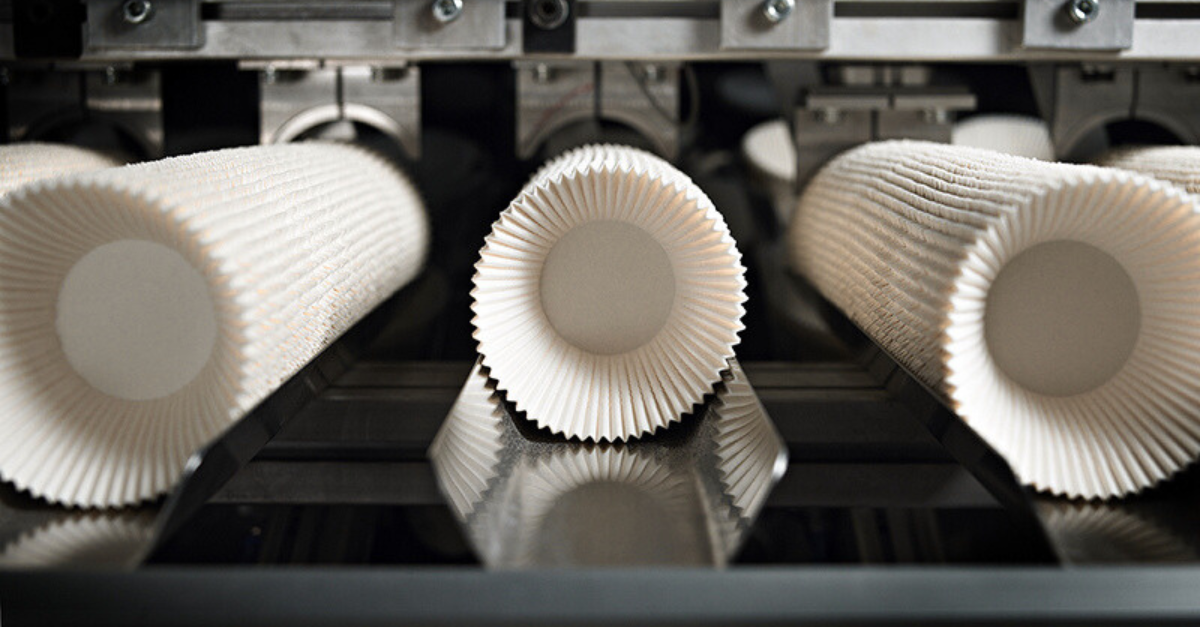

Our industrial baking cup

From there, nothing is left to chance: not the choice of material, not the tests, not the trials or simulations. Every curve, every thickness, every reaction to heat is analyzed, modeled, tested. These are all choices driven by those tasked with imagining a product that doesn’t yet exist, but must function flawlessly.

Once the design is finalized, swift decisions must be made. Reliable suppliers must be chosen. Timelines must be precise. Experience is essential. Meanwhile, others ensure that every machine is ready, every procedure up to date, every detail under control.

Then comes the moment when paper is transformed. Speed and precision come into play, but so do care and attention. Every detail is tested by those who ensure that the production cycle is not only efficient but also consistent and safe.

At the same time, there is a network of people coordinating every shipment, whether by sea, by air, or by land. Every single movement of the industrial baking cup is carefully scheduled along its journey: from when to ship, to how to package, to where each batch must go. It’s a process that usually remains hidden, yet it is essential to keep everything on track: meeting timelines, scheduled appointments, and strict deadlines.

It’s the invisible side of logistics, the invisible engine that makes the final result possible. Every minute counts. Every kilometer is calculated.

Behind the scenes, work continues on strategies, relationships, numbers, and perspectives. Customers are listened to, ideas are gathered, and needs are transformed into solutions. Day after day, this silent effort builds trust, creates connections, and keeps the entire process moving forward. It’s not only about delivering products, but also about anticipating challenges, finding opportunities, and ensuring that every detail contributes to a bigger picture. This is the ongoing dialogue between people, expertise, and vision.

In the meantime, the industrial baking cup has left the production line. It is ready to contain, protect, enhance.

A simple wrap for the final consumer, an extraordinary result of engineering, precision and responsibility.

Because behind every well-made product, there is an organization that believes in the value of work, precision, and quality. There are people who put passion into what they do, who dedicate time and attention to details that often go unnoticed but make all the difference. There is a vision that turns challenges into opportunities and ideas into tangible achievements.

And above all, there is the belief that true excellence comes from the balance between human dedication, collective effort, and the pursuit of continuous improvement.

All of it, in a simple industrial baking cup.

What do you think? Let us know in the comments of our LinkedIn company page!